Electrical Safety Signs and Symbols

|

| Electrical Safety Signs and Symbols |

The safe working procedure includes Safety precautions during the execution of work and shall the site shall be kept safe even after working hours are over.

All safety gears should be wore by the working persons and the equipment must be handled in correct way.

The instructions in simple form play a crucial role in such cases. But the time required to go through text material is more.

During emergency, the time required to react is very less so safety sign play a very important role.

Requirements of Safety Signs

The requirement of safety signs are as below:

>> It should be illustrative i.e.the person must understand its meaning easily.

>> It should convey the instruction easily.

>> It should be Pictographically so that it is easily understood by all persons.

>> Sometimes text is to be used. The text used should be easy to read and understand. Preferably it should be in local languages.

>> By seeing safety sign the person should be in a position to initiate immediate action.

>> Colour codes play an important role in conveying a message regarding safety. Each safety colour has a specific meaning. The colour of the sign specifies the nature of the sign.

- Red signs are prohibitive.

- Blue signs are mandatory.

- Yellow signs are warnings.

- Green is used for safe condition and first-aid signs.

Electrical Safety Signs and Symbols

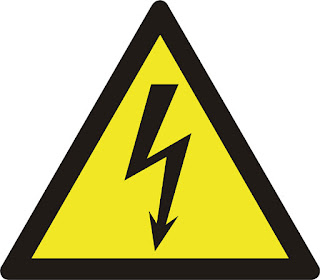

Some Electrical Safety Signs and Symbols which is use in industries and day to day life is shown below along with description:1. Warning sign

|

| Warning sign |

- Warning sign giving warning of hazard or danger.

2. Overhead Load

|

| Overhead load sign |

- There is a material handling going on by crane overhead.

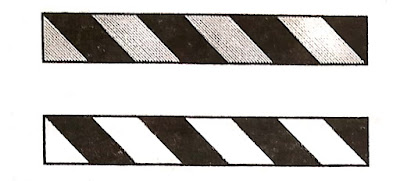

3. Caution sign

|

| Caution sign |

- There is obstacles in the way

4. Material Flammable

|

| Material flammable sign |

- The material is Flammable.

5. Direction Sign

|

| Direction signs |

- It used for route direction

6. Height Restrictions

|

| Height restrictions or Raised Platform sign |

7. Fire Exit Sign

|

| Emergency Fire Exit Sign |

8. First Aid Facility Sign

|

| First Aid Facility Sign |

9. Fire Extinguisher Sign

|

| Fire extinguisher sign |

Fire Classes and Their Prevention

Fire Classes and Their Preventions are described below:

Class A Fire

|

| Class A Fire Symbol |

Fire involving combustible material such as wood, paper, cloth, rubber, plastic requiring the heat absorbing effects of water, water solutions.

Class B Fire

|

| Class B Fire Symbol |

This type of fire involves flammable or combustible liquids, greases, petroleum products and similar materials for extinction, a blanketing effect is essential.

Class C Fire

|

| Class C Fire Symbol |

Which involves flammable gases, substance under pressure including liquefied gasses.

Here it is necessary to dilute the burning gasses at very fast rate with an inert gas, Dry chemical powder or carbon-di-oxide.

Class D Fire

|

| Class D Fire Symbol |

These fire requires special media to extinguish such as carbon-di-oxide special dry chemical powder.

Great job man keep it up also visit on this site https://techdinesh.com/

ReplyDeleteAll the safety signs and symbols are very important and useful in many places. Good blog post and was very informative to read. Thanks and keep posting more safety signs images.

ReplyDelete